Modern Movable Partition

Acoustics Table

The Industry accepted "measuring stick" for the acoustical performance of operable walls is the Sound Transmission class (STC) rating. Walls are tested under laboratory conditions with varying frequencies to determine how much a sound level decreases when It transmits from one side of the wall/partition to the other. This decrease is called Transmission Loss (IL)

For instance, if a sound measures at 60 dB on one side of a partition, and only 30dB on the other, then rating would be 30 dB at that particular frequency. Since common sounds cover a wide range of grequencies, Sound Transmission Class (STC) ratings are used to provide a single number rating to identify the Transmission Loss of a partition as it varies with frequency.

• Ceilings, floors and furnishings are Important to acoustic control.

• Flanking paths can significantly diminish the sound-reducing properties of an installed operable wall, but they can be avoided with proper building design and barrier installation.

â–ª Remember, the sound-reducing properties specified for the operable partition must be matched by the surrounding ceiling, walls ad floor.

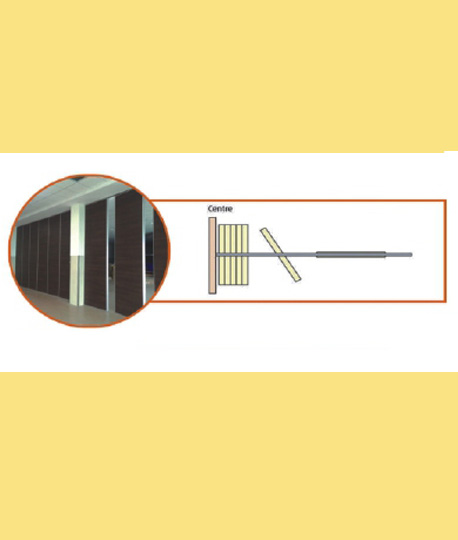

Closures Types :

We are offering two types of closure panels depending upon customer requirments.

Expanding panel

This panel has an over-sleeve that can be expanded sideways to lock the wall in place. This is operated by a removable handle in the face of the panel. Usually located at the stacking end of the wall.

Pros : Physically and acoustically locks the wall into place.

Cons : Not useable for access.

Door panel

Suitable on Standard height wails. The last panel is a full height door hinged off the fixed jamb or the prior panel. Doors are normally located at one end of the wall.

Typical width is 500-900mm.

Pros : Provides convenience access. Lowest cost closure option. Easy to Operate.

Cons : For centre stacked walls, the door may protrude slightly to the side of the stack.

Aluminium Track : The tracks are made from extruded 6063-T5 anodized aluminum. The track housing shall utilize grooves and interlocking steel pins for positive alignment of adjacent track sections, and shall be reinforced overhead by drop rod brackets. Aluminium track housing shal include an integral nut slot to accept a hardened square nut for attaching each drop rod bracket to the top of the track.

Trolley : Wheeled nylon trolley made with the base Material of POM 45 tempered steel shall be used as per approved stacking methods

Seals : Vinyl seal of butane rubber will be used as top and bottom as well as closure seals for the operable wall system. Retractable seal drop will be 23mm.

Horizontal Rail : Horizontal rail of extruded 6063-T5 anodized aluminium shall be used inside which a retractable box section will be present.

Vertical Rail : Vertical rail of extruded 6063-15 anodized aluminium shall be used where male / female profiles will be accommodated for panel Interlocking.

Panels : The panels will be made from 12mm MDF boards and shall be 100mm thick and 1230mm maximum width, made to the appropriate acoustic rating and structural banking and mounted in the full perimeterextruded aluminium frames with interlocking comer construction. The panel faces shall be finished with

Basic Panels shall be equal in module • Approx. Weight Kg/square meter : 38 kg

• Maximum height : 5500mm

Rectractable Mechanism : The top and bottom horizontal rail of each panel shall incorporate an extrided aluminium box section mechanical seal manually operated by a handle inserted in the panel stile, tumingthe handle through 45 degrees shall simultaneously extend or retract the top and bottom seals through steel and spring mechanism which shall firmly hold the seals in the retracted or extended mode. Single crank type mechanisms shall activate floor and head seals.

Magnetic Strip : Ferrite magnetic strip of 15.7x10.6x4.9 mm will be used in between aluminium vertical rails to enhance better panel interlocking.

Rock Wool : Rockwool plain slab of 64 Kg/m3 density, 50mm Thickness will be used for stuffing in between the two MDF boards of each panel for acoustical performance of the panel.

Lock Handle : A steel handle is used for locking each Individual panel, inserting In the panel stile at the luck holder distance of 850mm, cranking the handle through 45 degrees shall simultaneously extend or retract the top and bottom seals at the same instance.

Technical Details Installaction Support Details : The track can be suspended in a variety of ways such as

Beam Details : Beam Load will depend upon the applicationand project specification details. The suggested table below are only a guide and allow for the weight alone upto 5mm of deflection. All beams will required Job specific caluculation from the certifier.

Ideal structural support will depend on the applicaion and project specific details. The suggested beams below are a guide only and allow for the weight of the wall alone and up to 5mm of deflection. All beams will require job specific calculations from a certifying engineer and this table should not be relied upon for construction purposes.